Repairs

“Train, train, comin’ down, down the line

Train, train, comin’ down, down the line

Well, it’s bringin’ my baby ‘cause she’s mine, all mine

She’s mine, all mine”

I expected dirty, grease-stained floors, with little light filtering into the workspace where the Chicago Transit Authority maintains and repairs trains, switches, and the other equipment that moves close to 750,000 people around the Chicago-metro area each day. It takes close to 1,500 rail cars moving over 100 miles of track to accomplish the task. All of those rail cars must be serviced.

Imagine my surprise, then, when — thanks to Open House Chicago — I walked into the CTA’s Skokie Shops, 15 or so miles northwest of the Loop to find a naturally-lit workspace without a speck of dirt on the floor and all the equipment and tools neatly arranged. You could eat off the floors, including the iron roundtables that are used to move the cars in and out of the facility. My pants can attest to the cleanliness. To get the composition, I sometimes kneeled on the cement and iron. Not a grease stain or speck of dirt on the fabric.

CTA repair facilities have been at this location since 1926. The entire facility was rebuilt in 2000, with the old facility meeting the wrecking ball. The new shops include 236,700 square feet of area.

Project manager Sarah was our guide. For an hour, she systematically led a tour of the workshops, throwing out tidbit after tidbit about the rail system and the repair shops. We heard about the 2600, 3200, and 5000-series cars, their different sized wheels, and the new 7000-series, which will be highly computerized. She told us to pay particular attention to rail-car numbers the next time we ride the CTA rails: Two conjoined cars will always bear odd and even numbers.

When I asked, she assured me that the cars will not jump the elevated track, tumbling to the ground. She also eliminated my concern about wheels falling off, hitting me in the head as I walk below. The trains just don’t move that fast through the curves, and the weight assures that the cars stay in place, together with the indents in the wheels. Phew, I can stop worrying when I walk around the Loop, at least with respect to the trains. Who knows about the decades-old terra cotta or pane-glass windows?

Our journey began at the Howard Street Red Line station. It took about seven minutes on a three-car chartered train heading through suburban woods to reach the switch that transferred the train from Yellow Line tracks to the sidetrack leading to the sprawling warehouse-like facility.

Our 51-year old engineer, Choo Choo Ronnie, was dressed in classic train engineer bib overalls. He was wearing work gloves and a classic cap. He was accompanied by 10 or so conductors. All were retired CTA employees who love the CTA. They volunteer to maintain the Heritage Collection of cars. The new guys don’t have the know-how.

When I walked through the large door, I first encountered a room where seats were spray-painted. Fifty-feet along the main pathway, the room opened up, with attractive skylights above. I was in the area where the mechanics work on the cars. There were maybe ten rows with cars elevated above sunken pits. Santa’s Express was being prepped for the upcoming holiday season. An antique train was also undergoing work. The remaining trains were the familiar silver ones that I ride several times a week. In some cases, the wheel carriages had been removed. One of my favorite sights was the series of cases holding replacement windows in a variety of shapes and sizes.

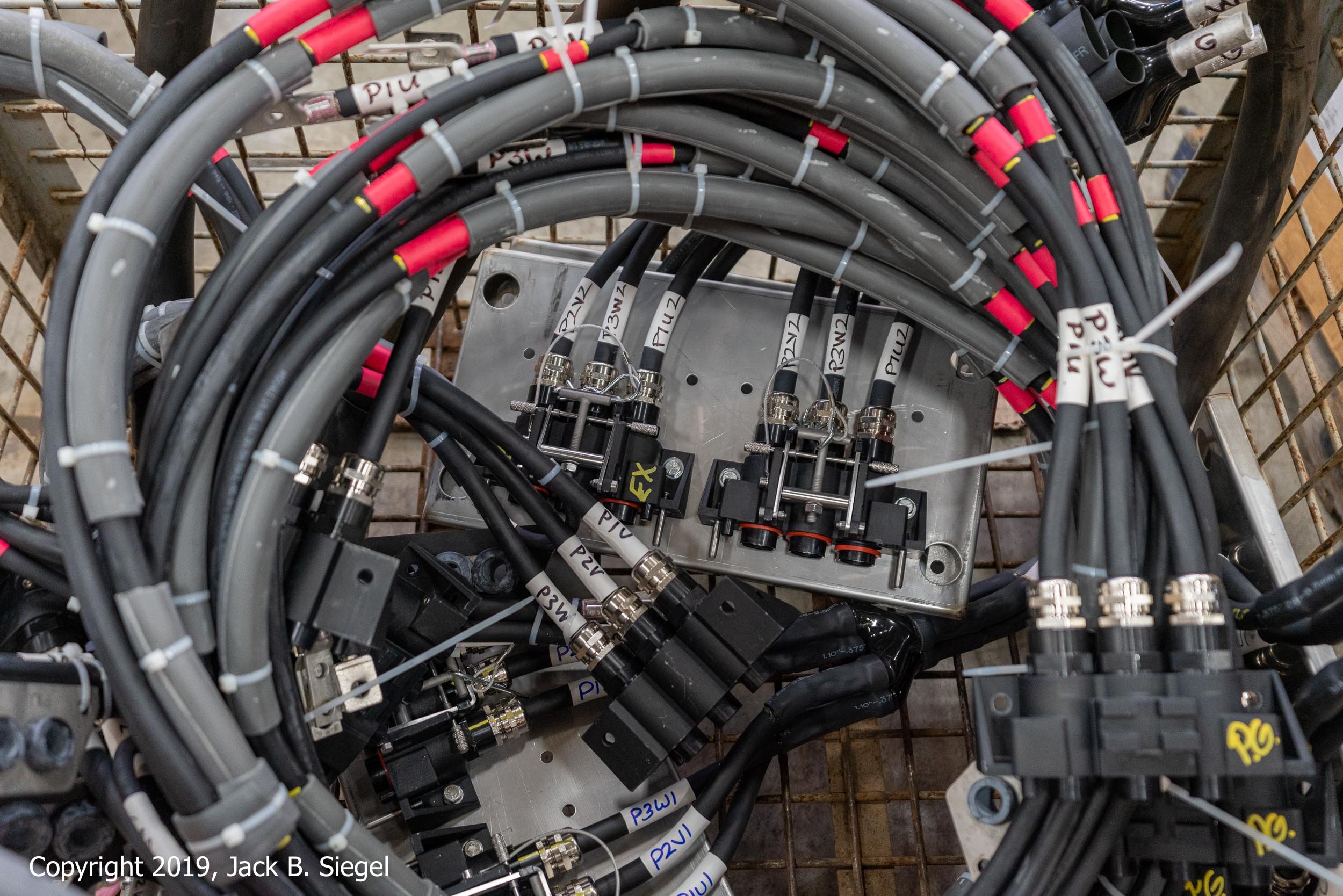

As we moved through the workshop, Sarah showed us the sections where switches, motors, and wheels are repaired or prepared for installation. Virtually every part has a number written on it.

I had assumed that this was a 24/7 operation, but it isn’t. The CTA operates two shifts during a five-day work week. Every car is inspected once every three months, and annually each car undergoes eight hours of maintenance.

End of the Red Line (Howard Avenue) and Start of the Journey to the Skokie Repair Shops

Choo Choo Ronnie Drives the Chartered Train

In Route in Vintage Carriage

The Paint Room

“Please Step Back; Hard Hat Required”

Wheels

Tank and Hoses

An Antique Car is Waiting for Repairs

Property of CTA Skokie Shop

Hoist in a Work Area

Replacement Windows of All Sizes and Shapes

“No Heavy Equipment on Grates”

The Underbelly

“Helping Hands”

Stacked Motors

Helping Hands Cafe

Time Cards

Computerization

Workers’ Compensation Notice

Parts

Big Wheels

Operator Instructions in Bulk

Don’t Fall In

Drill Press

Storage Closet

Sewer Engine and Car

“Do Not Operate Gantry Crane Beyond This Point”

Getting Santa’s Express Ready for the Upcoming Holiday Season

Back on the Tracks

Sidelined

Shocking

Choo Choo Ronnie Taking Me Home on a Train Bound for Glory